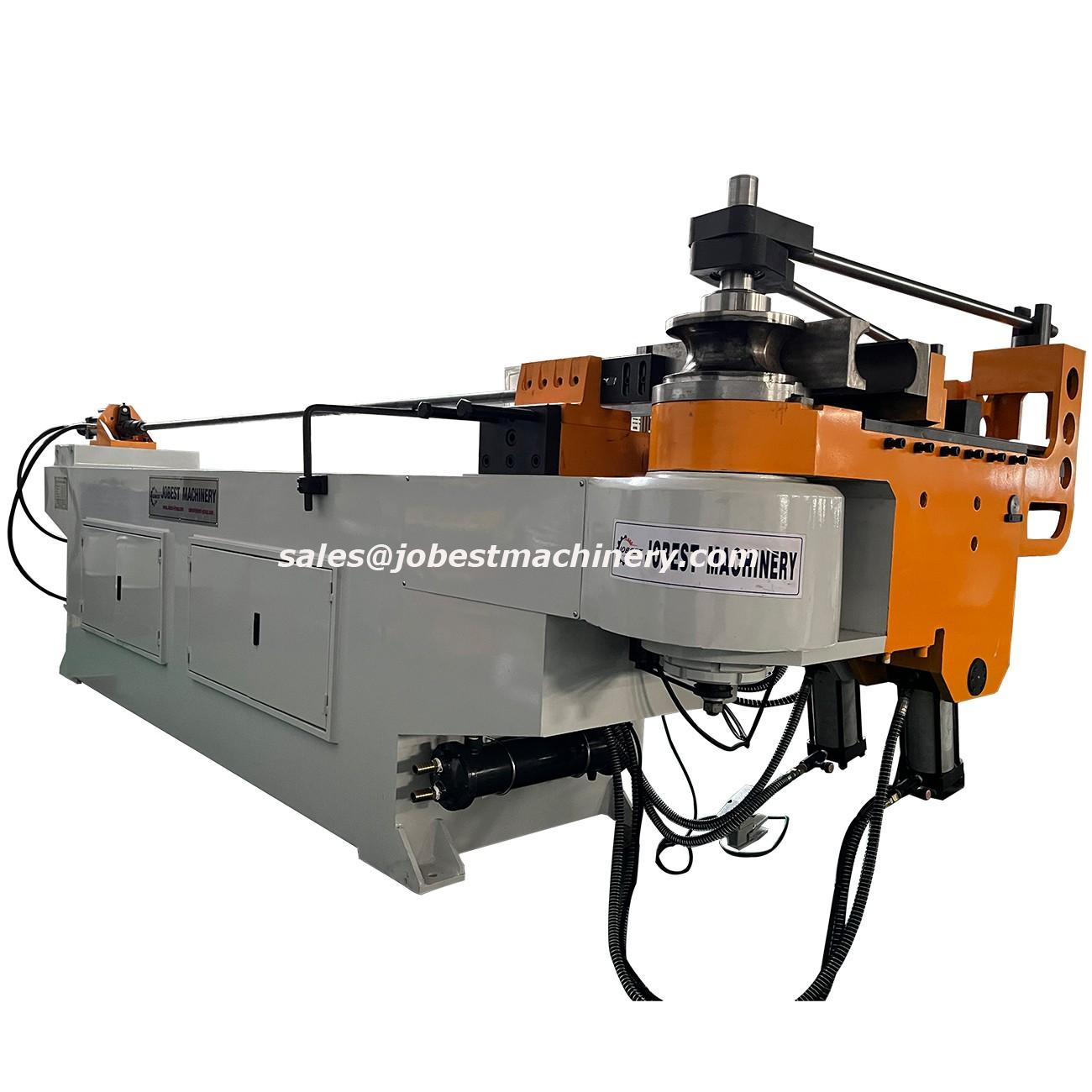

Product Description

1.PLC control, easy to set programs and operate .

2.Slowly returning of mandrel , make good shape and appearance of the angle .

3.Rotating is controlled by servo-motor, more precise .

4.Memory 100 sets records with each record setting 20 auto rotating and bending angles .

5.Moveable control platform with touch-screen , more convenient .

6.Mistakes self-checking on the screen , help to solve problem immediately .

7.Key parts use the imported brands .

8.Hydraulic power, processing more smoothly .

9.Die material use high quality steel, hardness high and long life use, the hardness not below HRC50; dies including bending die, clamping die, crease resistant die, guide die, Wiper Die(Optional), Ball Mandrel(Optional).

Product parameters

Main Technical Parameter | Unit | 18NC | 25NC | 38NC | 50NC | 63NC | 75NC | 89NC | 114NC | 130NC | 168NC |

Max. Bending Capacity | mm | 18×2 | 25×2 | 38×2 | 50×2 | 63×4 | 75×5 | 89×8 | 114×8 | 130×12 | 168×16 |

Bending Radius Region | mm | 20-150 | 20-180 | 20-200 | 20-250 | 25-350 | 30-350 | 30-450 | 40-550 | 50-650 | 60-850 |

Bending Angle Region | Degree | 0-190° | 0-190° | 0-190° | 0-190° | 0-190° | 0-190° | 0-190° | 0-190° | 0-190° | 0-190° |

Effective Length Over Mandrel | mm | 2000 | 2000 | 2000 | 2200 | 2500 | 3200 | 3800 | 4500 | 4600 | 4850 |

Oil Pressure System Motor | kw | 2.2 | 2.2 | 4.0 | 5.5 | 7.5 | 7.5 | 11 | 15 | 18.5 | 22 |

| Max. Pressure | kg/cm | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 |

Machine Dimension | mm | 2300×55 0×1300 | 2500×650 ×1300 | 2500×700 ×1300 | 3000×700 ×1300 | 3200×750 ×1300 | 3650×1000 ×1400 | 4400×1150 ×1350 | 5800×1500 ×1350 | 6000×1500 ×1350 | 6300×2450 ×1500 |

| Machine Weight | kg | 500 | 600 | 750 | 1220 | 1400 | 2380 | 4500 | 6500 | 11500 | 12000 |

JOBEST MACHINERY: BEST-QUALITY, BEST-SERVICE, BEST-PRICE!!! SEND INQUIRY

JOBEST MACHINERY TECHNOLOGY

JOBEST MACHINERY TECHNOLOGY